HIGH-TENSILE. WELDABLE. SCREW-ON TYPE.

Attachment points

by BRUGG Lifting

Attachment points for applications on construction sites, in logistics, in industral or production halls – BRUGG Lifting offers high-tensile eye bolts, weldable or screw-on type transport rings as well as sling swivels for different working loads.

To go with the attachment points offered by us, our product range also provides a large selection of lifting gear and slings as well as special lifting equipment according to customer specifications.

Right handling of attachment points

For reasons of safety, the right handling of attachment points is essential both for humans and materials.

That means: The number and arrangement of the attachment points have to be selected in such way that the load will not change into an unforeseen position during transport. Attachment points in strongly soiled areas or in areas where a point of interference occurs should be replaced with locking screws which should be color-coded to allow for an easy retrieval of the boreholes for the attachment point.

Please also note the following directions and instructions on the use and fastening of attachment points.

Correct mounting and fastening of attachment points

The attachment points must be affixed in such way that they can be reached easily and without obstacles for attaching and removing the sling gear.

The attachment point must not be obstructed by other constructional elements. It must be capable of aligning in all directions together with the sling gear. Any deflection or any slinging at sharp-edged components is not permitted.

The attachment points must be affixed in such way that no dangerous points (bruising, shearing, trapping or bumping) are produced endangering the slinger. They must not jeopardize the transport by protruding.

Turn the bolt completely to the plane contact surface and tighten it with the specified torque. Secure detachable attachment points remaining at the load against unscrewing and retighten them before the initial operation.

Affix inserted attachment points using a nut according to EN 4032, where the projecting end of the thread does not exceed twice the thread pitch P.

Attachment points: regulations and laws

Before use, the attachment points must be checked, e.g. by the slinger, for the bolt fit, strong corrosion, incipient cracks, deformations, clearance.

The attachment points must not be loaded in excess of the Working Load Limit (WLL).

During the construction of machine parts, entire machines or the like, the attachment points are already computed and designated for ensuring a safe and stable installation or transport of the load.

The attachment points EN 31000 can be affixed non-detachably (welded) or detachably (bolted).

When slinging the load all attachment points provided by the manufacturer have to be used in accordance with the specifications. Do not use eye bolts or lifting eye nuts that are unsuitable for such purpose.

Material | Thread depth |

|---|---|

Steel | 1,00 x thread-⌀ |

Cast iron | 1,25 x thread-⌀ |

Aluminum | 2,00 x thread-⌀ |

Aluminum magnesium alloy | 2,50 x thread-⌀ |

Did you know ...

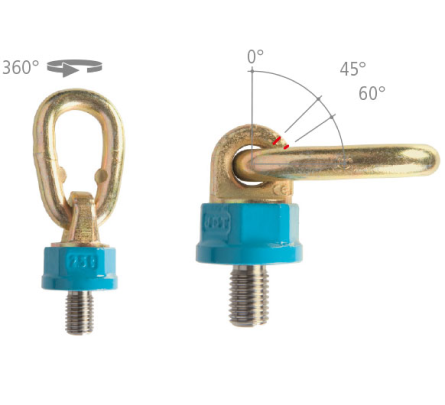

… that the working load limit can be increased using the Theipa Point sling swivel by at least 25% with retention of the known functional dimensions? The forged hexagonal bolt at the swivel body allows for an easier assembly and disassembly; bruise marks prevent kinks of the link; a galvanic coating provides protection against corrosion.

More information on this sling swivel is provided in our catalog and our web shop .

Attachment points from our web shop

Our web shop offers various attachment points for different working loads: starting with secure and industrial safety (EKAS guidelines) tested sling swivels to transport rings and eye bolts.

Special Features of BRUGG Lifting Anchoring Points

BRUGG Lifting offers high-quality anchoring points that are essential for efficient and safe lifting operations. Our anchoring points are known for their outstanding quality and reliability. Here, you will learn more about the special features of our anchoring points and why choosing BRUGG Lifting is the right decision.

What is an Anchoring Point?

An anchoring point is a specialized device used for lifting and securing loads. It serves as a connection element between the lifting equipment and the load. Anchoring points can come in various shapes, sizes, and constructions, suitable for different applications. They ensure a secure attachment and enable the efficient execution of lifting operations.

Advantages of Anchoring Points

Anchoring points offer numerous advantages for lifting loads. They provide a safe and reliable attachment, ensure even load distribution, and reduce the risk of damage. With their robust construction and high-quality materials, they offer high load-bearing capacity and long service life. Anchoring points are versatile and enable efficient lifting operations in various fields.

Materials of Anchoring Points

The materials used in the manufacturing of anchoring points play a crucial role in their performance and durability. At BRUGG Lifting, we use high-strength steels and corrosion-resistant materials to ensure that our anchoring points withstand high demands. By employing high-quality materials, we offer anchoring points that guarantee reliable and secure attachment, even in challenging conditions.

General Selection Criteria for Anchoring Points

Choosing the right anchoring point is essential for safe and efficient application. There are various factors to consider during the selection process, such as load-bearing capacity, application area, environmental factors, and the type of load. At BRUGG Lifting, we are ready to assist you in selecting the optimal anchoring point that meets your requirements and ensures the highest level of safety.

Load-Bearing Capacity of Anchoring Points

The load-bearing capacity of anchoring points is a critical criterion when selecting the right anchoring point. It indicates the amount of weight the anchoring point can safely carry without overloading. At BRUGG Lifting, we offer anchoring points with different load-bearing capacities to meet the diverse requirements of our customers. Our anchoring points are tested and certified according to international norms and standards to ensure safe and reliable performance.

Advantages of Screwable Anchoring Points

Screwable anchoring points provide a simple and flexible attachment solution. They can be fastened at various locations and easily removed when needed. Screwable anchoring points are particularly suitable for applications that require regular adjustment or changing attachment points. They offer high load-bearing capacity and ensure a secure fixation of the load.

Advantages of Weldable Anchoring Points

Weldable anchoring points provide a permanent and stable attachment solution. They are directly welded to the supporting structure, creating a solid connection. Weldable anchoring points are ideal for applications that require a permanent attachment. They are characterized by their high load-bearing capacity and reliability, ensuring long-term safety.

Attachment points: the optimal solution for every application

BRUGG Lifting’s attachment points provide a secure and reliable means of fastening loads while ensuring even load distribution. These attachment points are constructed using high-strength and corrosion-resistant materials.

Explore our range of other products as well, and rely on BRUGG Lifting to deliver the optimal solution for your requirements: