ROBUST. DURABLE. FOR EFFORTLESS WORKING

Forest equipment

Existing products and individual custom-made devices

Forest chains, forest ropes, choker ropes and the matching accessories from BRUGG Lifting make your everyday forestry work easier. Whether designed as steel rope, synthetic rope or steel chain –the robust and durable forest equipment for logging and skidding lets you work clearly more effortlessly.

If you are interested, please contact us or browse through our online shop and catalog under the heading of forest equipment.

Forest equipment for every use

To be equipped for every use in forestry work, different forest equipment is needed depending on the specific requirements. The brief overview below shows forest equipment suitable for your projects and how to handle such equipment correctly.

Forest steel cable or forest plastic rope?

- 10x lower weight of the forest equipment for an easy, effortless handling when logging and skidding.

- No injuries to the hands caused by broken wires or steel chips.

- High level of safety due to reduced setback in case of wire breakage.

- Easy coiling onto the winch.

- Less injuries or incisions on standing trees.

- Fast repair of the forest equipment in case of rope breakages, as a loop splice can be fabricated on site within 15 minutes.

- Robust synthetic rope with special UV-Schutz.

- Resistance to fuels, oils, water and frost.

- Safety due to quality-assured and tested chains and accessories

- Weight reduction due to optimal utilization of the material strength

- High service life due to extreme wear-resistance

- Flexibility due to comprehensive range of accessories

- Good grip due to the special square cross-section

- Weight reduction of approx. 25% as compared to G8 forest equipment

- Extremely high breaking load at equal weight

- Increased wear-resistance in ground traction mode

PRINCIPLES

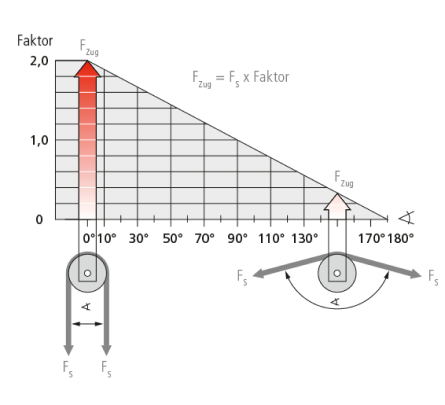

Loading of guide rollers and pulley blocks.

The stated safety factors relate to tree-felling and skidding works in “normal cases”, i.e. without special risks. Tree-felling and skidding works involving “special risks”, e.g. due to the immediate vicinity of highways, railway lines and buildings, require special safety measures to be taken and the safety factors to be adjusted to the specifications for lifting gear.

Forest equipment for every use

How to work in a sustainable manner using our forest equipment: splicing our Dynalight synthetic rope by yourself is very easy.

1. Mask the sheath behind the splice end with adhesive tape, mount the splicing needle and fix it with adhesive tape.

2. Measure and mark 60-80 cm (or 3-4 times the hand spread) behind the splicing needle. 1.

3. Determine and mark the length L of the desired loop. 2.

4. Puncture the splicing needle on the 2nd marking in the center of the rope.

5. Pull the loop together until the markings 1 and 2 lie on top of each other and secure the loop with a punctured splicing needle.

6. Puncture a 2nd time after about 5 cm (or 3-4 strands).

7. Puncture a 3rd time after about further 5 cm (or 3-4 strands)

8. Puncture and insert the splice end after further 5 cm (or 3-4 strands) in direction towards the center of the rope.

9. Bevel the sheath above the adhesive tape.

10. Pull the sheath tightly over the protruding rope end.

11. Pull the sheath tightly over the protruding rope end.

12. The splice is finished and fully resilient.

The accessories matching our forest equipment

If we have aroused your interest, apply for your ReBOX today.

If you access to PVS, you can do this conveniently within the application.

Forest equipment from our web shop

Our range offers robust and durable forest equipment. Visit our web shop and select the matching product from our range.