TRANSPORTATION OF GOODS OPTIMALLY SECURED.

Load securing

To secure your freight optimally for the road-borne, rail-borne, waterborne and airborne transportation, you can rely on the load securing products of BRUGG Lifting. In addition to tension straps, lashing chains, strapping belts, edge protection and non-slip mats, we also offer comprehensive advice by our sales force, as well as professional safety checks of your lashings by our inspection service.

Optimal load securing

lashing down and diagonal lashing

In addition to safe loading and unloading, a proper load securing against tipping, sliding and losing for different types of means of transportation like train, truck, ship or airplane must also be provided for. Thus, the load should, whenever possible, be secured in addition through a positive lock against sliding, which, for example, can be perfectly provided through slinging, layer pads or wedging.

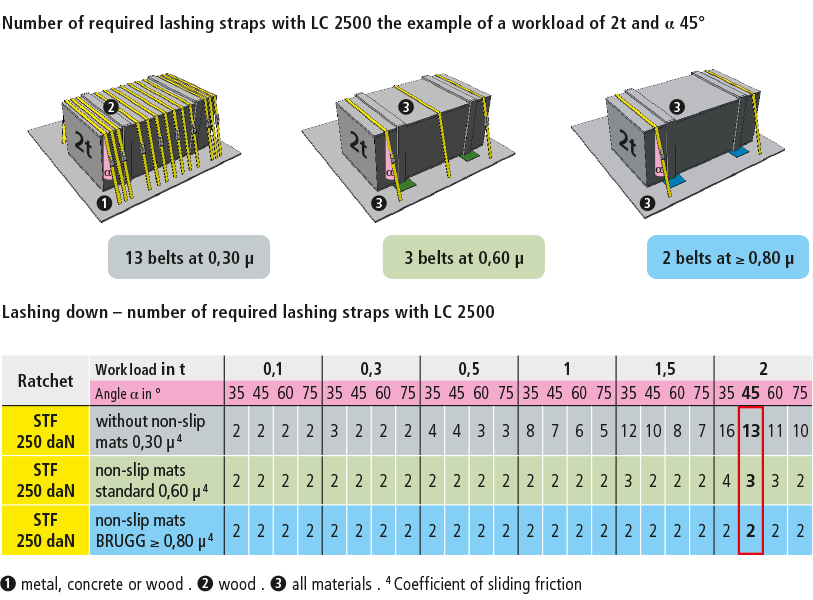

What to take into account with lashing down of loads?

Compute, in accordance with the relevant standard EN 12195, the number of lashings required for lashing down, where the standard tension force (STF) is 50% on the side opposite to the clamping device. At least two traverses are required for homogeneous free-standing loads. However, this only applies to stable, i.e. non-tipping goods.

Loose materials such as boards, rods and other non-homogenous loads must be initially clamped securely in themselves when the load is secured.

In addition, care must be taken that loads and loading areas are not strongly soiled and are not greasy, oily or icy.

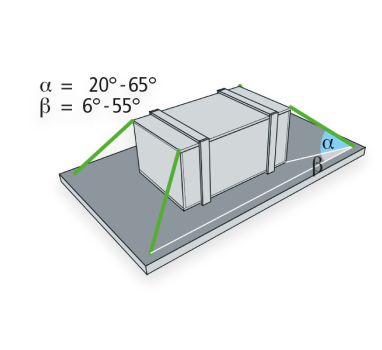

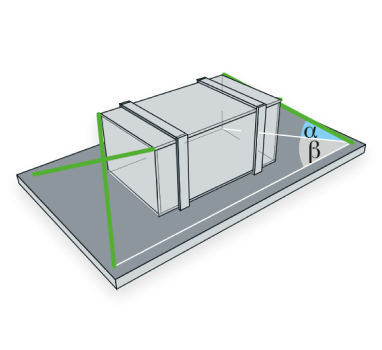

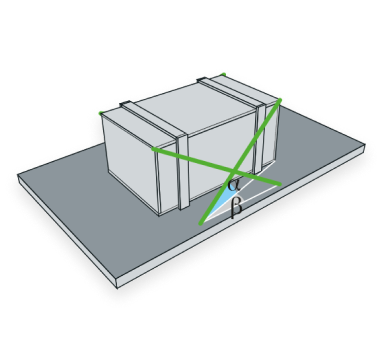

Diagonal lashing – LC with 4 lashings

This table was prepared for the angular ranges of α = 20° to 65° and β = 6° to 55° to assist in load securing. The required lashing capacity (LC) was computed for the most disadvantageous pairs of angles in each case. Please make sure in diagonal lashing that the attachment points at the load and loading area also feature the corresponding strength. The LC values in the table were rounded up to the effect that they conform to the applicable LC of the available lashings. For instance, a 10 mm lashing chain has a LC of 6300 daN. D The LC of the lashing is the lower, the higher the coefficient of friction μ is. By exactly determining the lashing angle a lower LC value can be computed as well.

Necessary LC for securing a load with 4 lashings each featuring an admissible tensile force in the direct leg of (daN):

Disadvantageous angular ranges and dimensions of the load can be balanced applying the crossover method.

Did you know …

… that we have developed a free app for calculations when securing loads?

For lashing down, BRUGG.Lashing lets you calculate the minimum number of lashings by entering the lashing angle, the given standard tension force and the coefficient of friction. For diagonal lashing, the app lets you calculate the minimum lashing capacity (LC) when using 4 lashings from the given load weight, lashing angle and coefficient of friction.

Download now:

We will be pleased to help you

If you have questions, suggestions or wishes, please contact us. To do this, simply click on one of the buttons below.