SAFE. PROVEN. WITH A WIDE RANGE.

Wire ropes from BRUGG Lifting

by BRUGG Lifting

High-quality wire ropes from BRUGG Lifting. BRUGG Lifting provides a large range of wire ropes and steel ropes, such as hoist ropes, drive ropes, Diepa ropes and special ropes, as well as various rope end connections like shackles, thimbles and loops. Proven in use at construction sites, in production halls, at industrial sites, etc., for many years.

If you are interested, please contact us or browse through our online shop and catalog.

How is a wire rope constructed?

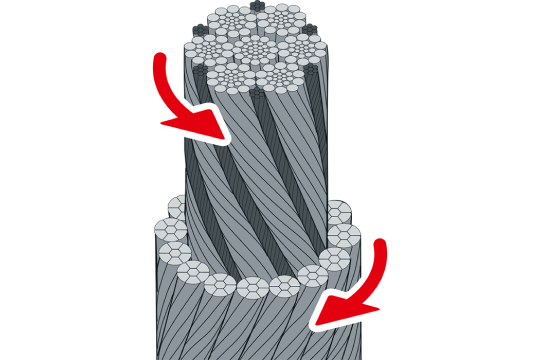

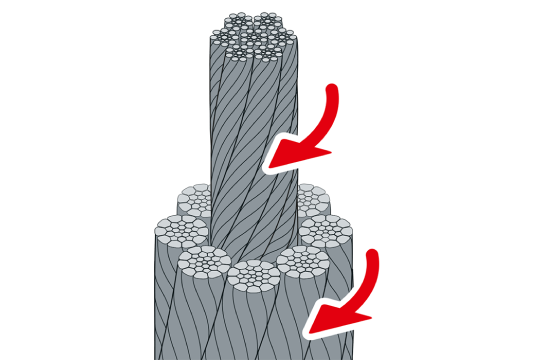

Steel wire ropes are constructed from a large number of steel wires. The single steel wires are converted into strands. Afterwards, several strands are stranded to form one rope core around which the outer strands are laid in a final stranding process.

Some rope constructions feature plastic inserts. For this purpose, the final stranding is preceded by a further production step during which a special procedure a plastic coat is applied onto the rope core. It is of course important to establish a sufficient amount of lubricant in the inner layers of the rope.

Selection of the appropriate wire rope

When selecting the appropriate wire rope, you must consider the rope properties, the type of the rope and the rope end connections. Here we give you an overview of the key aspects and selection criteria.

If you need further information about how to select the appropriate wire rope, we will assist you. Just contact us by telephone or email.

Rope properties

The key rope properties to be considered when selecting the appropriate wire rope include the rotation freedom and the direction of lay.

Rotation-free or non-rotation-free?

This decision must be made very carefully. There is no room for error. Short rope service lives, changes to the structure of the rope, abrupt and unexpected failure of the rope, etc. could result from a wrong choice.

Rotation-free ropes

Rotation-free ropes must be selected when lifting an unguided load on a single rope line or when lifting an unguided load on several rope lines at great lifting heights. Rotation-free ropes can be used with or without a swivel.

Non-rotation-free ropes

Non-rotation-free (non-twisting, rotation-resistant) ropes must be selected when lifting guided loads, when lifting unguided loads on several rope lines at small lifting heights (e.g. electric hoists) or when lifting loads with right-hand and left-hand ropes operating in pairs. Non-rotation-free ropes must not be used with a swivel.

What is a rotation-free wire rope?

A steel wire rope is considered as rotation-free, if the rope under the influence of an unguided load does not, or does barely, rotates around its longitudinal axis and exerts a very low torque on the end connections. This characteristic results from the fact that direction of lay of the rope core is opposite to the direction of lay of the rope itself. Thus, when a rotation-free rope is under load, the torque generated by the core is equalized by the torque generated by the outer strands.

What is a non-twisting wire rope?

A steel wire rope is considered as non-twisting if, when the rope is cut, the wires do not, or do barely, pop out of the rope structure even without the rope being served and the pulled rope remains straight without resilience.

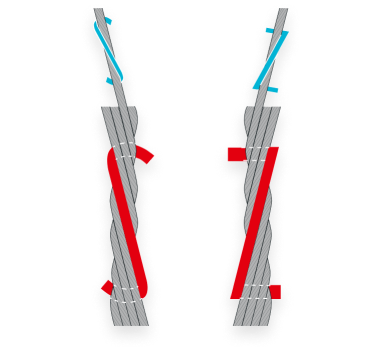

The correct direction of lay

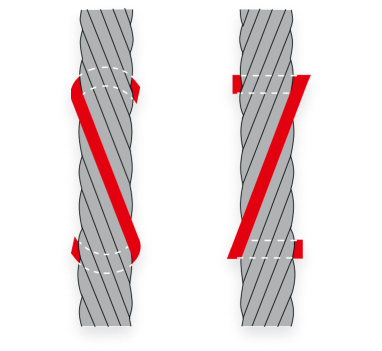

The direction of lay of the rope is the direction of the helical line of the outer strands, where we distinguish between right-hand lay and left-hand lay. Both the rope and the strands feature a direction of lay.

Ordinary lay

The wires in the outer strands are laid in the opposite direction to the lay of the strands in the rope.

Lang lay

The wires in the outer strands and the strands in the rope are laid in the same direction.

Tip

As a general rule according to DIN 15020, for a grooved drum having a right-hand pitch a left-hand lay rope should be applied. Accordingly, for a grooved drum having a left-hand pitch a right-hand lay rope should be used.

The appropriate type of rope

The rope application determines the wire rope construction that may be used.

- Use spiral ropes for static or virtually static applications

- Use stranded ropes for all normal rope drives

- Use spiral ropes with round strands for rope drives requiring a rotation-resistant rope

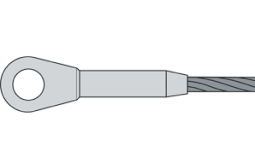

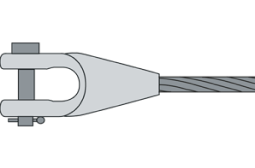

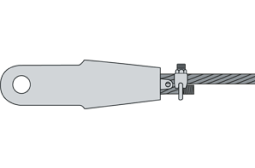

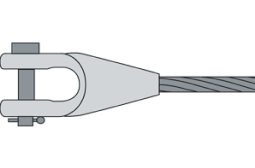

Rope end connections in comparison

Most end rope connections will reduce the minimum breaking strength of the ropes. The overview shows some common designs with the remaining minimum breaking strength of the rope in %.

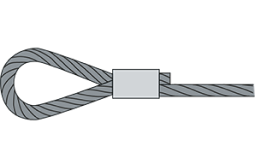

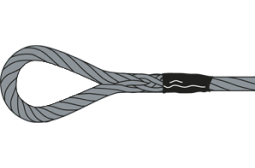

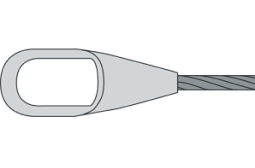

> 90% Crimped loop EN 13411-3

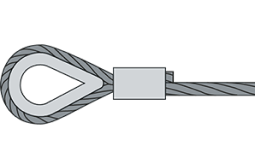

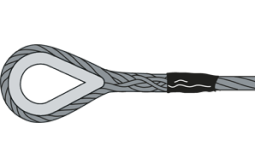

> 90% Pressed thimble EN 13411-3

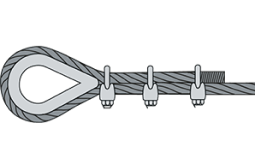

> 80% Loop/thimble with stirrup rope clamps acc. to EN 13411-5.

Not to be used for rope slings!

> 90% Spliced loop BRUGG

> 80% Spliced loop EN 13411-2

Loops must be secured against untwisting!

> 90% Spliced thimble BRUGG.

> 80% Spliced thimble EN 13411-2

Loops must be secured against untwisting!

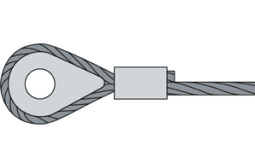

> 90% Pressed solid thimble EN 13411-3

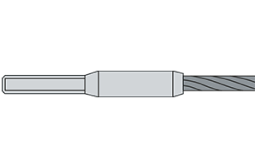

> 90% Clamp thread (inside-outside-thread) with standard ropes BRUGG

> 80% Clamp thread (inside-outside-thread) with special ropes BRUGG

> 90% Clamp head with eye BRUGG

> 90% Clamp head with clevis BRUGG

> 80% Asymmetric rope lock EN 13411-6

> 80% Symmetric rope lock EN 13411-7

100% Cast head with clevis EN 13411-4

> 90% Crimped loop EN 13411-3

Please note that most end rope connections will reduce the minimum breaking strength of the ropes.

DID YOU KNOW …

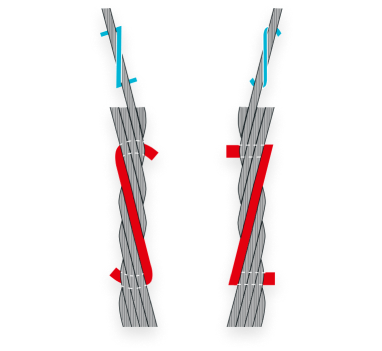

...the various discard criteria for wire ropes?

These include wire breaks, broken strands, reduction of the rope diameter due to internal or external wear, internal or external corrosion, decrease of elasticity, deformations, waviness, bird-caging or protrusion of the core or parts thereof, protrusion of wires from the outer strands, rope swelling, damage caused by heat, crushes, flattened spots, kinks, bends or similar damage.

If you detect one of the above anomalies in your wire ropes, select new ropes from our catalog.

New wire ropes from our online shop

Visit our online shop and stock up on new, secure and industrial safety (EKAS guidelines) tested wire ropes. Our large range will definitely provide the suitable product.