SAFE. PROVEN. WITH A LARGE SELECTION.

Lifting slings, round slings and textile slings

from BRUGG Lifting

Our special range for the most diverse requirements for safe lifting of loads-

The right textile lifting gear for all cases

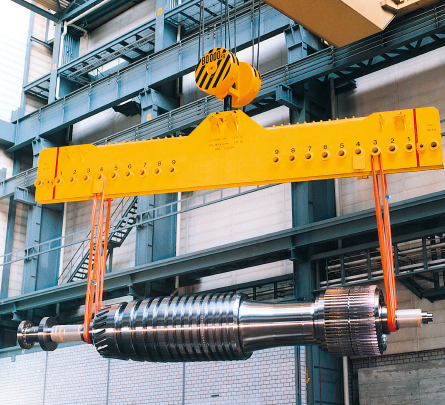

Whatever loads you want to lift, you’re sure to find the right work equipment for your project in our wide product range. Choose from our textile slings if you want to lift particularly slippery or sensitive loads. Ideal, for example, for rollers, shafts, finished parts or painted objects. Natural fiber ropes and man-made fiber ropes are very suitable for pressure-sensitive and relatively light loads, such as pipes, heating or ventilation parts.

Caution

For sharp-edged and hot loads, neither lifting slings nor round slings are suitable, but sling chains or ropes.

How to choose the right textile lifting equipment?

With textile slings from BRUGG Lifting you can lift almost any load on construction sites, in production halls, industry and co.

Our range includes:

- Lifting slings from 1 strand up to 4 strands

- Reversible slings with different hooks

- System construction slings with all-round chafing protection

- Round slings, endless slings and lifting slings

- Accessories such as replacement chains, replacement straps, suspension links, textile couplers and much more

n addition to the common products from these areas, you will also find suitable lifting points and special lifting equipment (also according to customer specifications) in our extensive sling and lifting equipment range.

Load capacity of lifting slings and round slings

All our lifting slings and round slings have a sewn-on load label that informs you about all important data – including the material, the manufacturer, the applicable standard and the date of the next test. Also on the load label you will find information on how to use the lifting slings and round slings. This includes the sling types, the angle of inclination, the working length and the Working Load Limit (WLL).

As a support for our customers, we offer with the BRUGG Lifting App the possibility to quickly and easily calculate the slings and the WLL.

Application instructions for your lifting slings, round slings and textile slings

To ensure that you are on the safe side when slinging loads, we have compiled some application notes for lifting slings and round slings for you.

Slinging of loads

- Does the safety catch of the load hook move properly?

- The safety catch of the hook must lock!

- Report any defect to the crane operator/supervisor

- Is the sling gear undamaged (no cracks, cuts, crushes, noses)?

- Can the load be transported using the selected sling gear?

Can the material be transported in this state using the crane (intact packaging, stable wooden pallet, no loose parts)?

- Where to attach the sling gear at the material to be transported?

- The material to be transported must be transported in balanced position. Take the center of gravity of the load into account!

Sling chains, belts or ropes tightly around the material to be transported, so that the load will not be shifted when lifted.

- Safe hold

- Alternative places, if the load tends to make uncontrolled movements

- Eye contact to the crane operator

- No danger of falling down and being trapped

- Signal to crane operator “slowly lift” by hand

- Supervise the lifting operation from short and safe distance

- If the load floats narrowly above the floor, check whether: the load is suspended balanced and the attachment points remain stable?

- If yes: Signal “Lift” by hand

- If the load tilts over or if attachment points shift: signal “Stop” by hand

- Never correct floating load by hand!

- Leave the swivel range of the crane

- Never stay below the floating load

Lifting slings, round slings and textile slings from our online shop

In our webshop you will find a wide range of high quality, safe and EKAS approved lifting slings, round slings, endless slings, lifting sling construction and reversal slings as well as various accessories.